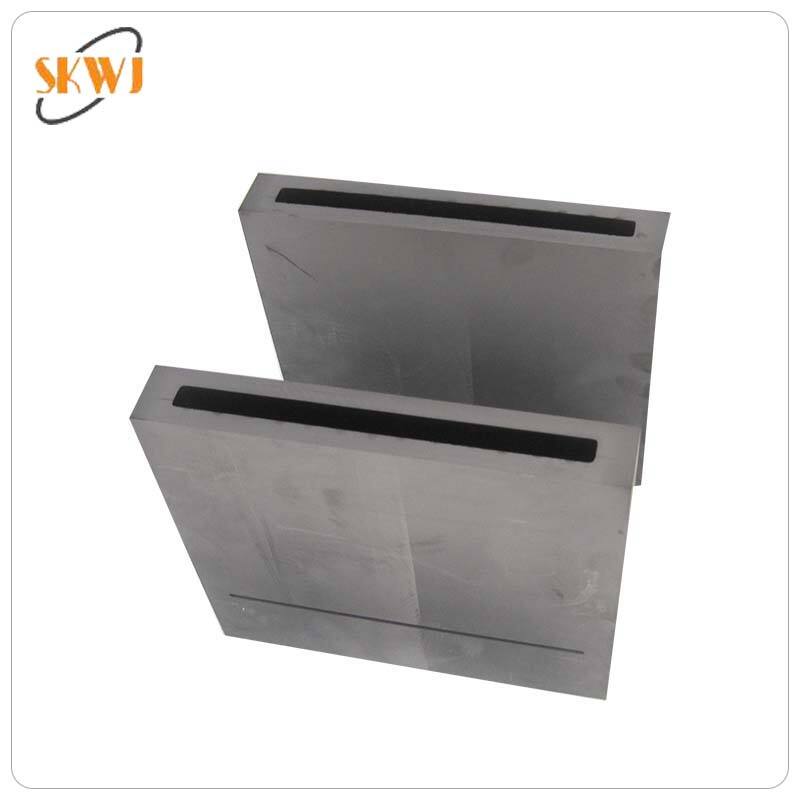

graphite die supplier

A graphite die supplier serves as a crucial partner in various manufacturing processes, specializing in the production and distribution of high-quality graphite dies essential for modern industrial applications. These suppliers provide precision-engineered graphite dies that are fundamental to processes such as electrical discharge machining (EDM), continuous casting, and metal extrusion. The dies are manufactured using advanced carbon materials and state-of-the-art machining techniques, ensuring exceptional thermal conductivity, dimensional stability, and wear resistance. Modern graphite die suppliers employ sophisticated quality control systems and computerized manufacturing processes to maintain consistent product specifications and meet diverse industry requirements. They typically offer customization services, allowing clients to obtain dies tailored to specific applications, from automotive components to electronics manufacturing. The supplier's expertise extends beyond mere production, encompassing technical consultation, design optimization, and after-sales support to ensure optimal die performance and longevity. These suppliers maintain extensive inventory systems and efficient logistics networks to guarantee timely delivery and minimize production downtime for their clients.