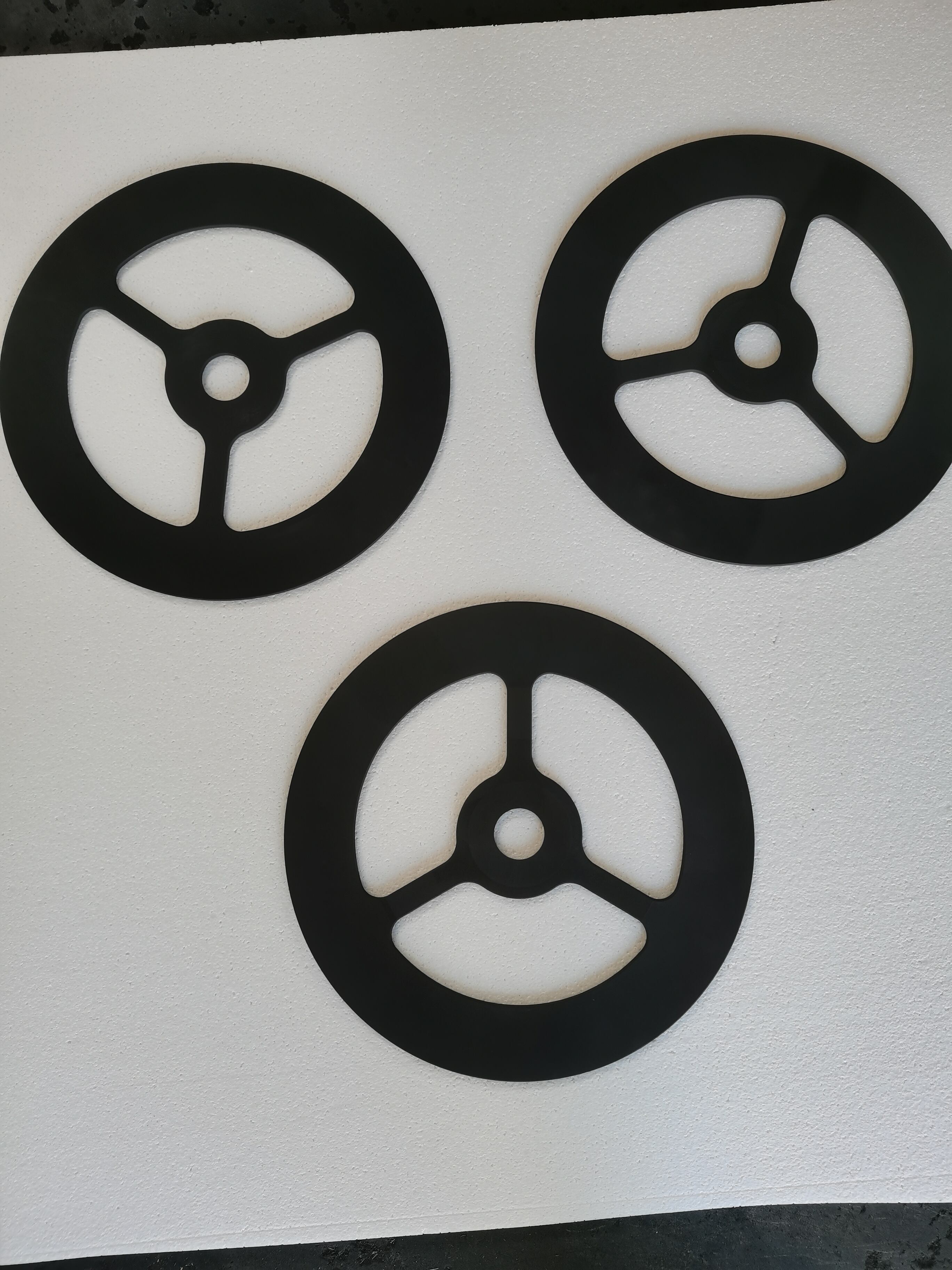

graphite die

A graphite die represents a crucial tool in modern manufacturing, specifically designed for precision molding and forming operations. This specialized equipment, constructed from high-quality graphite material, serves as a critical component in various industrial processes, particularly in powder metallurgy and hot pressing applications. The die's structure incorporates carefully engineered cavities and channels that facilitate uniform material distribution and precise shape formation. Its unique composition allows for exceptional thermal conductivity and stability at high temperatures, making it ideal for applications requiring consistent heat distribution. The graphite die's molecular structure provides natural lubricity, reducing the need for additional release agents and minimizing wear during the molding process. Advanced manufacturing techniques ensure precise dimensional accuracy and surface finish, while the die's design accommodates complex geometries and intricate details. These dies are extensively used in producing ceramic components, carbon-carbon composites, and various metal parts, offering reliable performance in demanding industrial environments.