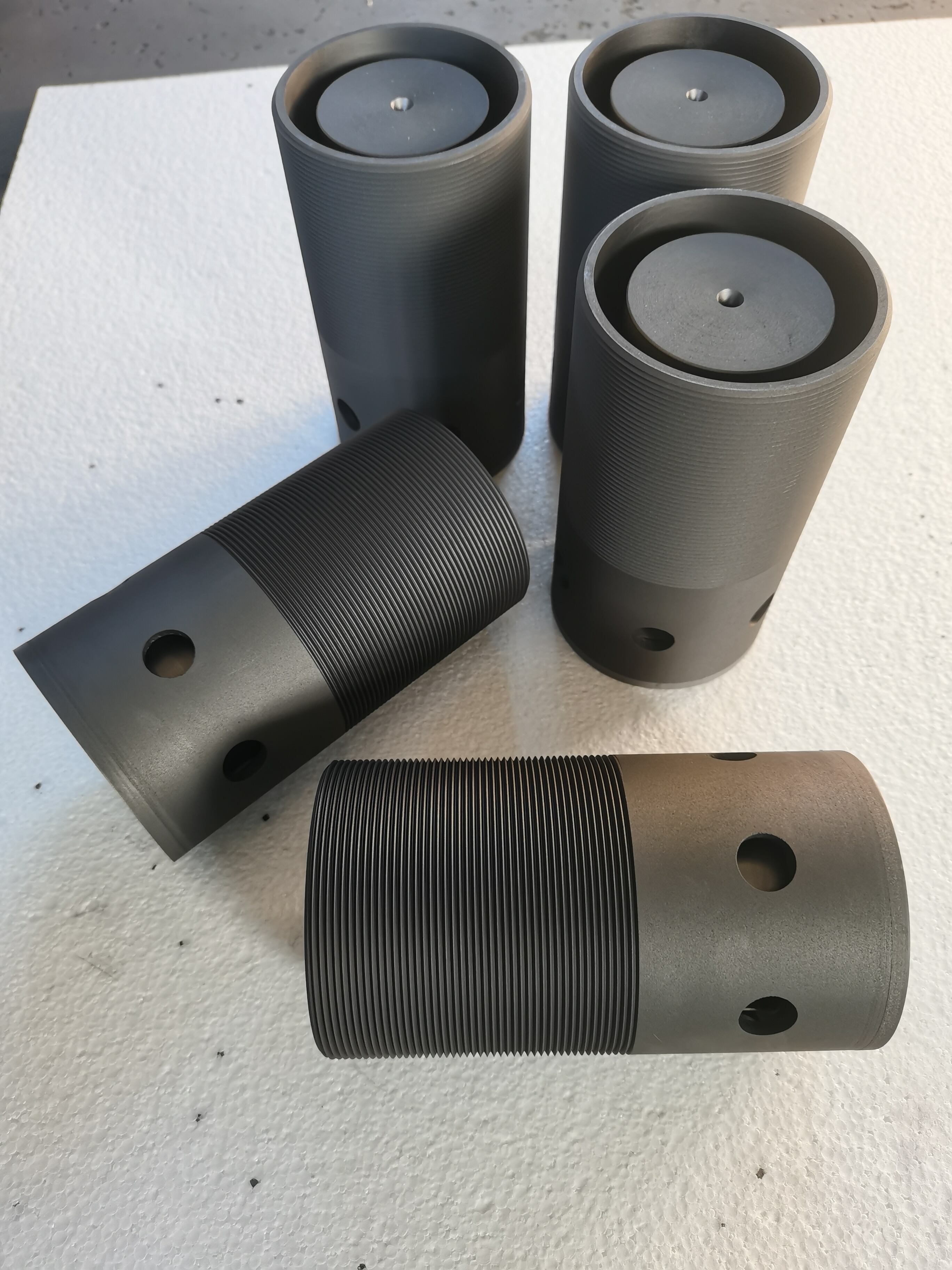

graphite die made in china

Graphite dies made in China represent a cornerstone of modern industrial manufacturing, offering exceptional performance in metal forming and molding processes. These precision-engineered tools are crafted from high-quality graphite materials, featuring superior thermal conductivity and excellent resistance to high temperatures. Chinese manufacturers have mastered the art of producing graphite dies that maintain dimensional stability even under extreme conditions, making them ideal for various metalworking applications. The dies are manufactured using advanced CNC machining technology, ensuring precise tolerances and consistent quality across production runs. These graphite dies excel in applications such as continuous casting, metal extrusion, and powder metallurgy. Their unique properties include low thermal expansion, outstanding wear resistance, and superior lubricity, which significantly reduces the need for additional lubricants during the molding process. Chinese graphite dies are particularly valued for their cost-effectiveness without compromising on quality, making them a preferred choice for manufacturers worldwide. The dies undergo rigorous quality control measures, including detailed surface finish inspections and dimensional accuracy tests, ensuring they meet international standards for industrial use.