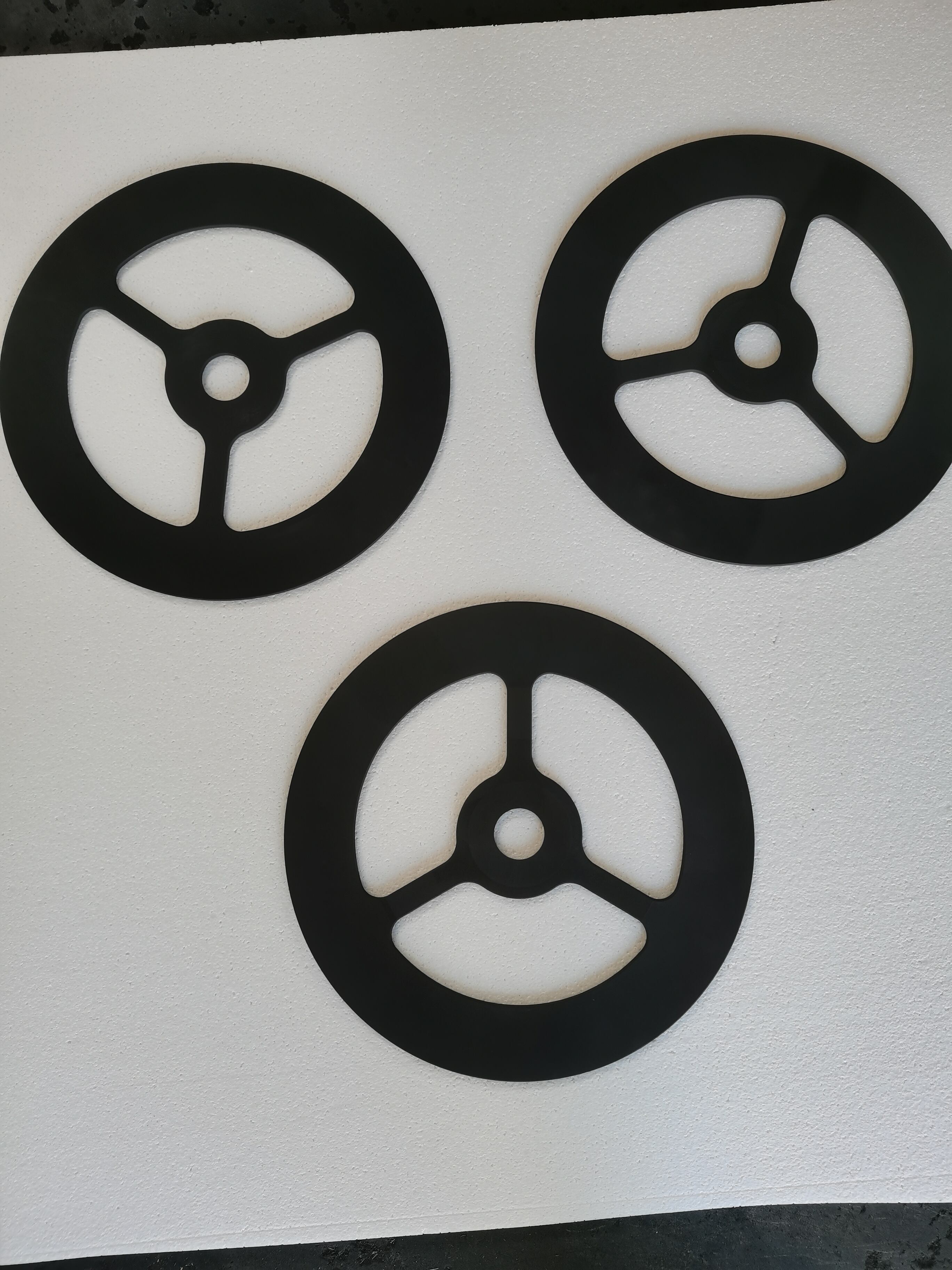

graphite molds for casting

Graphite molds for casting represent a crucial advancement in metallurgical engineering, offering a reliable and efficient solution for metal casting processes. These specialized molds are manufactured from high-quality graphite materials, engineered to withstand extreme temperatures and provide superior thermal conductivity. The molecular structure of graphite ensures excellent thermal stability, making these molds ideal for continuous casting operations. Their primary functions include maintaining dimensional accuracy, facilitating smooth metal flow, and ensuring consistent heat distribution throughout the casting process. The technological features of graphite molds encompass their non-wetting properties, which prevent metal adhesion and enhance release characteristics, their exceptional thermal shock resistance, and their ability to maintain structural integrity under repeated heating and cooling cycles. These molds find extensive applications across various industries, particularly in precious metal casting, automotive parts manufacturing, and jewelry production. Their precision and reliability make them especially valuable for creating intricate components that require high dimensional accuracy and surface finish quality. The molds can be precisely machined to accommodate complex geometries and are particularly effective in applications requiring fine detail reproduction.