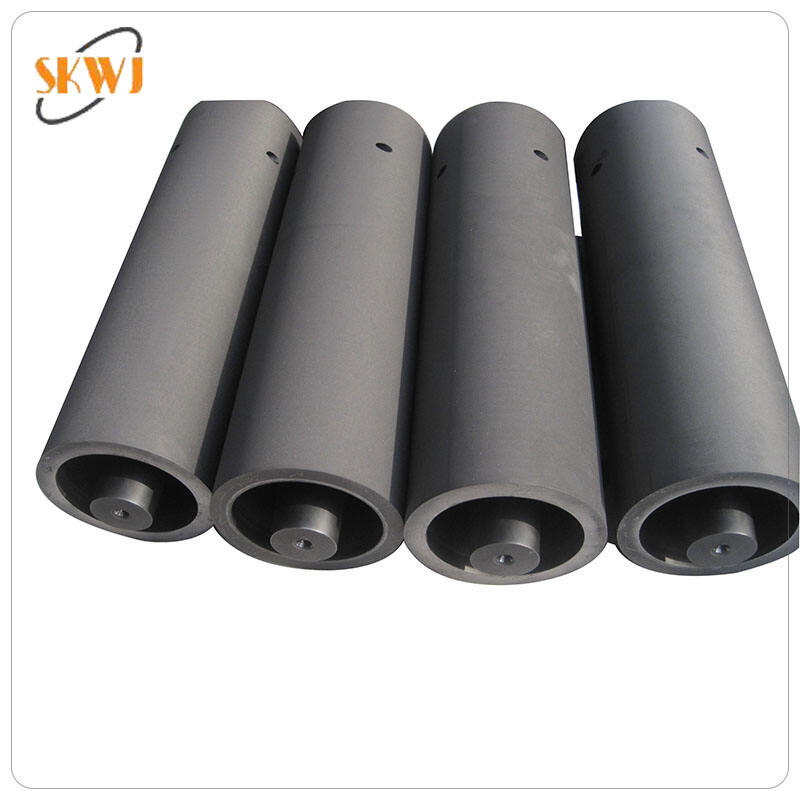

custom graphite molds for gold

Custom graphite molds for gold casting represent a crucial advancement in precious metal manufacturing, offering exceptional precision and reliability in the production process. These specialized molds are engineered using high-grade graphite materials that can withstand extreme temperatures while maintaining dimensional stability. The molds feature carefully designed cavities and channels that facilitate optimal metal flow and solidification patterns, ensuring consistent quality in each casting. Their thermal conductivity properties allow for controlled cooling rates, which is essential for achieving desired metallurgical properties in gold products. The molds are precision-machined to accommodate various gold casting requirements, from simple ingots to intricate jewelry components. They incorporate advanced design elements such as proper venting systems to prevent air entrapment and ensure complete cavity filling. The custom nature of these molds enables manufacturers to create specific shapes and sizes according to their production needs, while the graphite material's natural lubricity prevents metal adhesion and enables easy release of cast pieces. These molds can be used repeatedly without significant degradation, making them a cost-effective solution for gold casting operations.