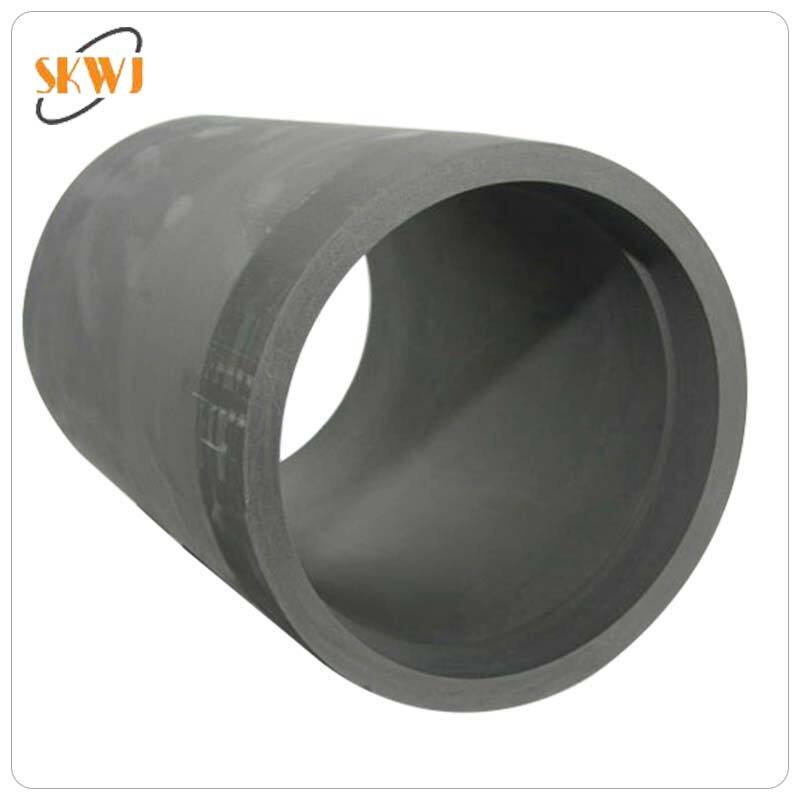

graphite molds for sale

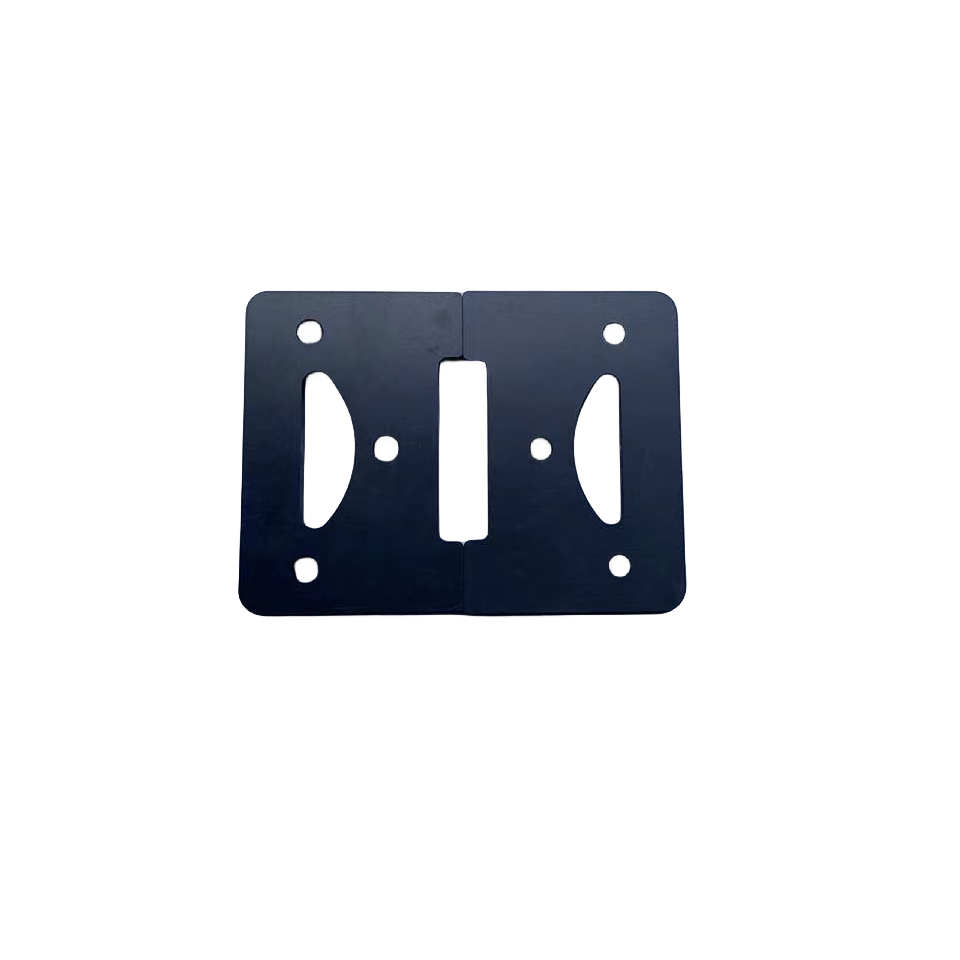

Graphite molds for sale represent a cutting-edge solution in industrial manufacturing, offering exceptional thermal conductivity and durability for various casting applications. These precision-engineered molds are crafted from high-grade graphite materials, ensuring optimal performance in high-temperature environments up to 3000°C. The molds feature sophisticated design elements, including precise dimensional accuracy and superior surface finish, making them ideal for producing complex metal and ceramic components. The molecular structure of graphite provides natural lubricity, reducing the need for additional release agents and facilitating easier part removal. These molds excel in applications ranging from continuous casting of metals to the production of semiconductor components and specialized ceramic products. The advanced manufacturing process ensures consistent quality across batches, with computer-aided design integration enabling customization to meet specific production requirements. Each mold undergoes rigorous quality control measures, including thermal stability testing and dimensional verification, guaranteeing reliable performance throughout its service life.