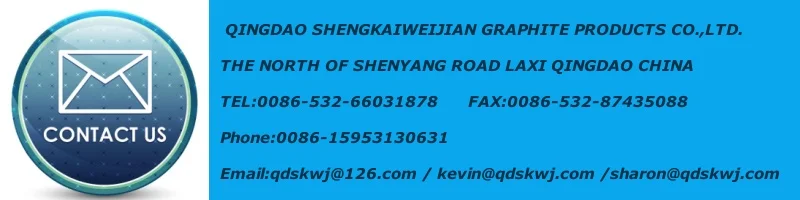

Product Description

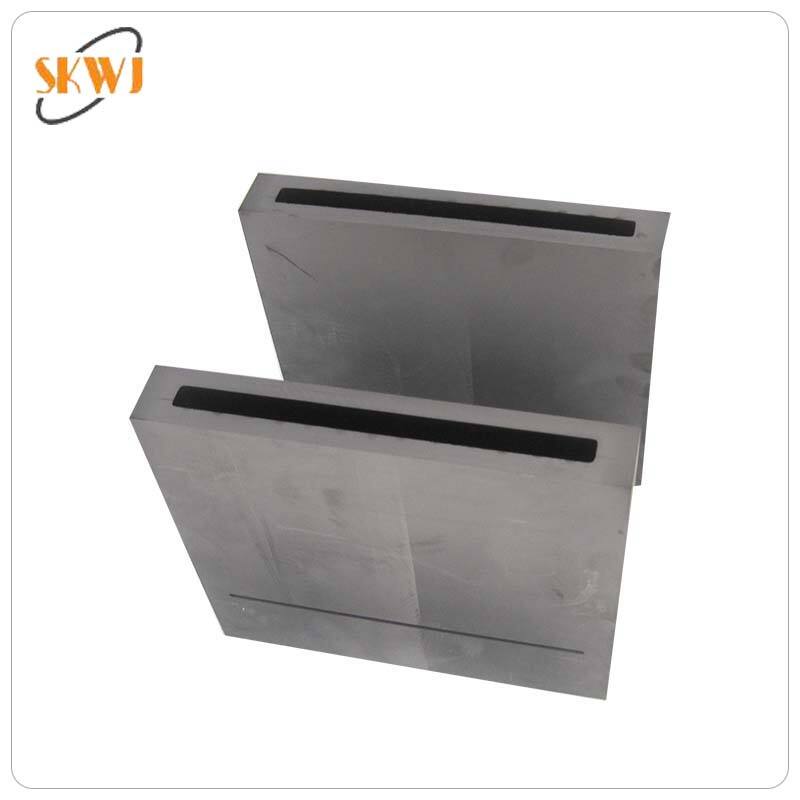

High quality graphite flat molds for copper plate casting

Feature:

1. Thermal stability: According to the quench acute thermal using conditions of graphite crucible, we will specially design the production procedure, so as to ensure the reliability of product quality.

2. Corrosion resistance: Even and fine basic design will delay the erosion of crucible.

3. Impact resistance: Graphite crucible can bear high thermal impact, so any process can be carried out.

4. Acid resistance: The adding of special materials will greatly improve the quality of crucible, especially its index of acid resistance., and will prolong the service life of graphite crucible.

5. High heat Conduction: High content of fixed carbon ensures the good heat conduction, shorten the time of dissolution, and remarkably reduce the energy consumption.

6. Control of metal pollution: The component of material under strict control will ensure that graphite crucible will not pollute the metals when dissolving.

7. Quality stability: The process technology of forming under high pressure and quality guarantee system will fully ensure the stability of quality

Graphite molds Materials index:

1.Content: 99.99%

2.Density: 1.88g/cm³

3.Compressive strength: 65mPa

4.Shore hardness: 55

5.Porosity: 15%

6.ash:0.1%

Application:

1. Brass continuous casting mould

2. Red copper continuous casting mould

3. Continuous casting mould for jewelry of gold, silver, platinum, etc.

4. Steel and stainless steel continuous casting mould.

By the shape of the cast product, it is divided into round bar mould, hollow tube mould, plate mould, and shaped mould.

FAQ

Q:When can i get the price?

We usually quote within 24 hours after getting your detailed requirements,like drawing,size,quantity ,specification etc. .

Q: Do you provide samples?

Yes, samples are available for you to check our quality.

Q:What about the lead time for mass product?

The lead time is based on the quantity,sample need about 2-7days.bulk need about 7~20days.

Q:Product packaging?

Packed in sponge+paper box+export wood cases,or according to your requirements

Q:About the price on Alibaba

Please note that the price on Alibaba is a rough price.The actual price will depends on raw materials,exchange rate ,wage and your order quantity .

Hope to cooperation with you,Thanks !