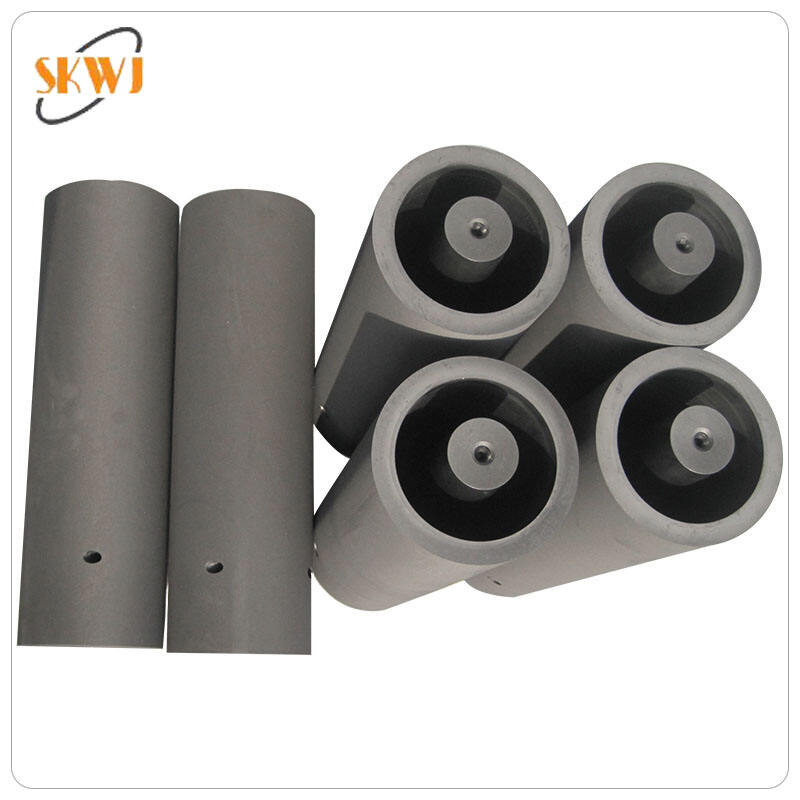

large graphite mold

Large graphite molds represent a crucial advancement in industrial manufacturing, particularly in metal casting and forming processes. These specialized tools are engineered from high-quality graphite materials, offering exceptional thermal conductivity and resistance to high temperatures. The molds are precision-crafted to accommodate various sizes and shapes, making them ideal for producing complex metal components. Their unique composition allows for rapid heat transfer while maintaining dimensional stability, ensuring consistent product quality across production runs. The graphite material's natural lubricating properties facilitate easy release of cast parts, reducing the need for additional release agents and minimizing production delays. These molds are specifically designed to withstand repeated thermal cycling, featuring reinforced structures that prevent warping and degradation under extreme conditions. The surface finish of large graphite molds is carefully engineered to achieve optimal casting results, with controlled porosity that aids in gas evacuation during the casting process. Modern manufacturing techniques enable these molds to be produced with precise tolerances, incorporating cooling channels and other specialized features that enhance their performance in demanding industrial applications.