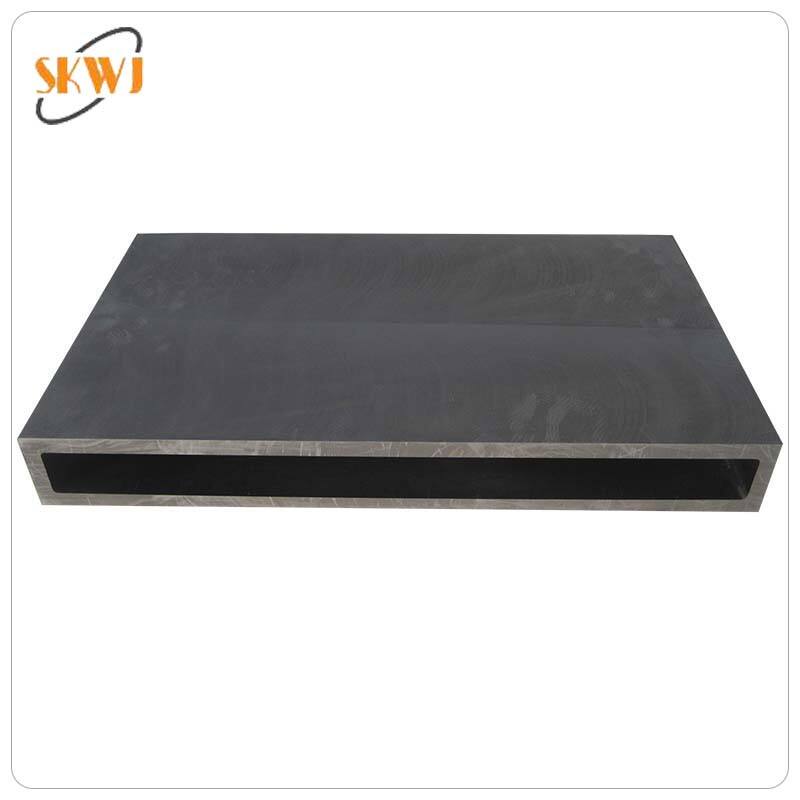

graphite use

Graphite, a versatile form of crystalline carbon, stands as a crucial material in modern industry and technology. This naturally occurring mineral combines exceptional thermal and electrical conductivity with remarkable mechanical properties, making it indispensable across various applications. In industrial settings, graphite serves as a vital component in electrodes, lubricants, and refractory materials, owing to its high temperature resistance and chemical stability. The material's layered structure, composed of carbon atoms arranged in hexagonal patterns, enables it to function effectively as a dry lubricant, reducing friction in mechanical systems without the need for oil-based products. In the energy sector, graphite plays a pivotal role in lithium-ion batteries, serving as the primary material for anodes. Its ability to intercalate lithium ions while maintaining structural stability makes it essential for modern energy storage solutions. Additionally, graphite's applications extend to nuclear reactors, where its neutron-moderating properties are crucial for controlling nuclear reactions. The material's versatility is further demonstrated in its use in pencils, brake linings, and various carbon-based materials for high-tech applications.