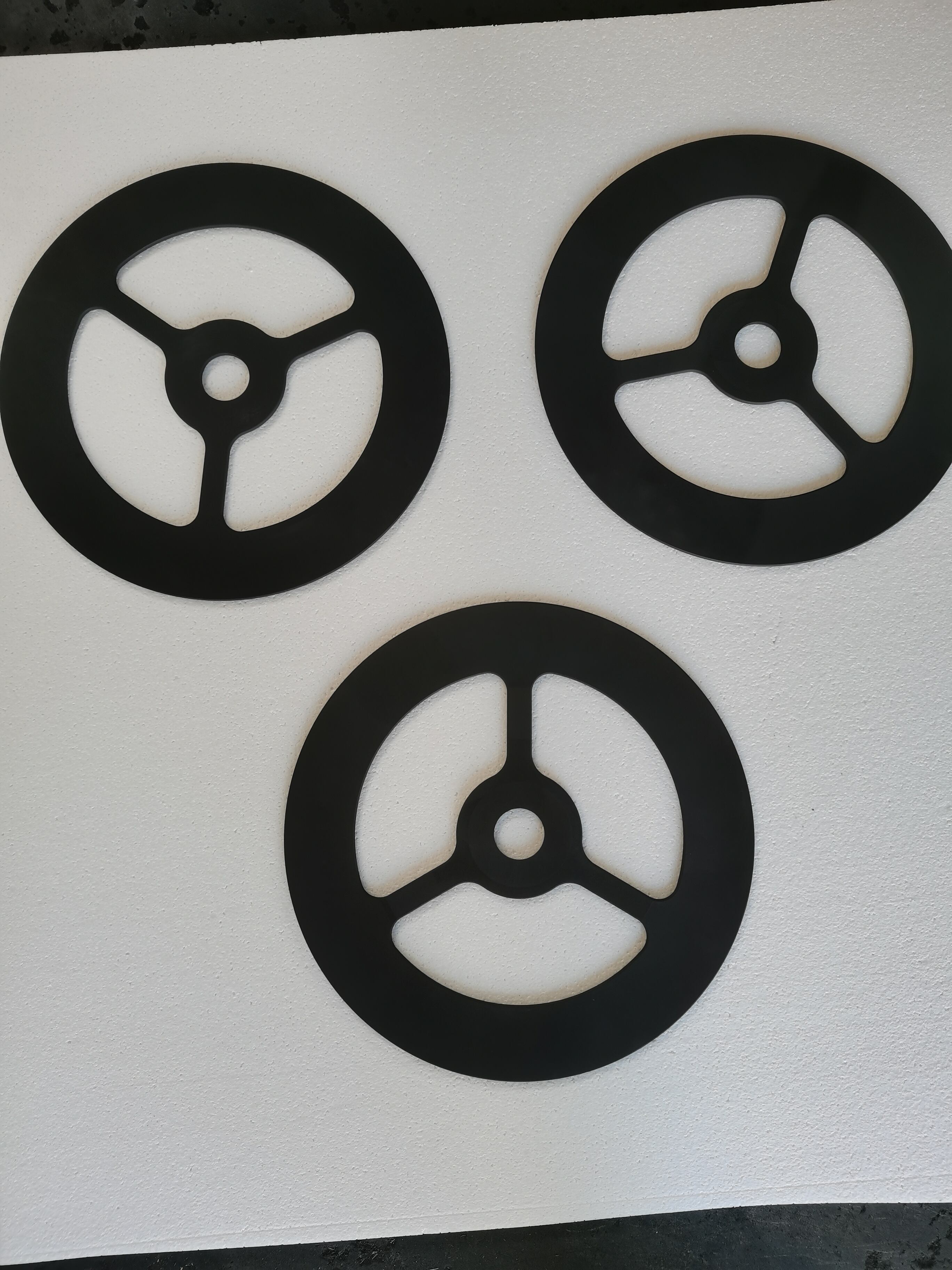

graphite molds for copper

Graphite molds for copper are essential tools in the metal casting industry, designed specifically for handling molten copper and its alloys. These specialized molds combine the exceptional thermal properties of graphite with precision engineering to create reliable and efficient casting solutions. The high thermal conductivity of graphite enables rapid and uniform heat distribution, ensuring consistent cooling rates and superior end product quality. These molds feature carefully engineered surfaces that facilitate smooth metal flow and prevent defects in the final castings. The material composition allows for multiple casting cycles while maintaining dimensional stability, making them cost effective for both small batch and high volume production runs. The molds are particularly valuable in applications requiring intricate details and precise dimensions, such as electrical components, industrial machinery parts, and decorative items. Advanced manufacturing techniques ensure these molds possess excellent resistance to thermal shock and oxidation, extending their operational lifespan. The design typically incorporates specialized cooling channels and venting systems that optimize the casting process and enhance product consistency.