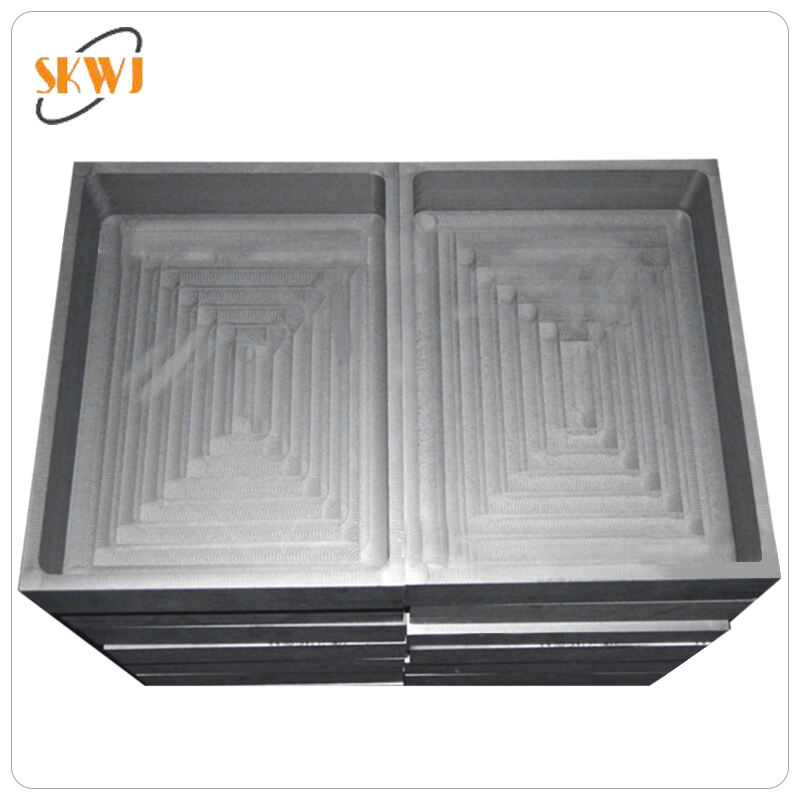

machining graphite

Machining graphite is a specialized manufacturing process that involves shaping and forming graphite materials into precise components through various cutting operations. This sophisticated process requires specific expertise due to graphite's unique physical properties, including its layered structure and brittleness. Modern machining techniques utilize advanced CNC equipment and specialized cutting tools to achieve exceptional precision in producing graphite components. The process encompasses various operations including milling, drilling, turning, and grinding, each requiring careful consideration of cutting speeds, feed rates, and tool selection. Machining graphite finds extensive applications in multiple industries, particularly in aerospace, semiconductor manufacturing, and metallurgy. The process is crucial for creating high-precision components such as electrodes for electrical discharge machining (EDM), heating elements, crucibles for metal casting, and various specialized industrial components. The ability to maintain tight tolerances while working with graphite is essential, as many applications require extremely precise dimensions and surface finishes. Modern machining centers equipped with dust collection systems ensure clean and efficient processing while maintaining workplace safety standards.