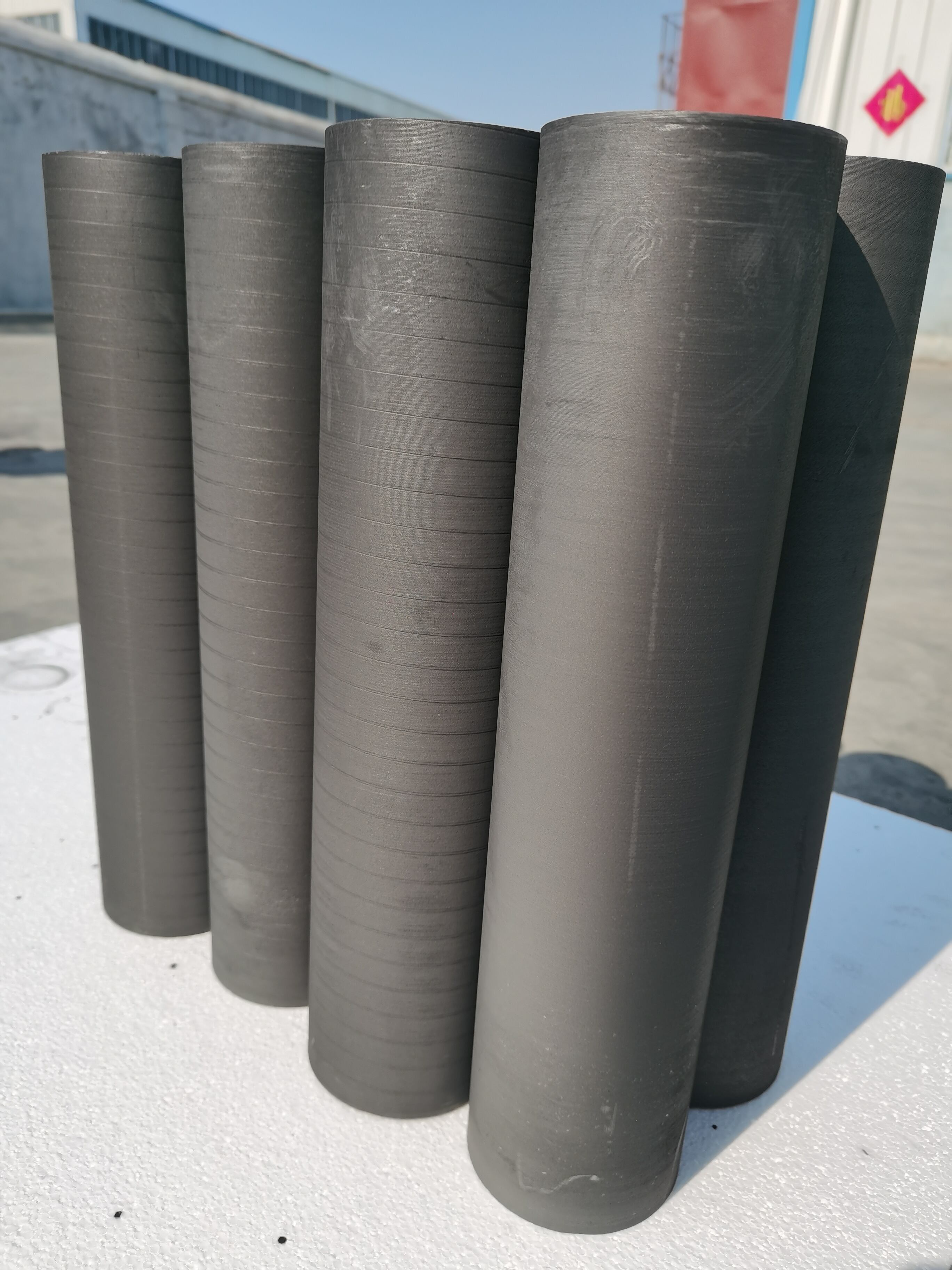

graphite condenser

A graphite condenser represents a crucial technological advancement in heat exchange and thermal management systems. This specialized equipment utilizes high-quality graphite material to facilitate efficient heat transfer and condensation processes in various industrial applications. The graphite condenser's primary function involves converting vapor or gas into liquid form through cooling, while maintaining exceptional chemical resistance and thermal conductivity. The device's construction features precision-engineered graphite blocks with internal channels designed to optimize flow patterns and heat exchange efficiency. What sets the graphite condenser apart is its ability to handle corrosive substances and maintain performance at high temperatures, making it particularly valuable in chemical processing, pharmaceutical manufacturing, and specialized industrial applications. The graphite material's natural properties enable superior heat transfer rates while resisting chemical degradation, ensuring long-term reliability and reduced maintenance requirements. Modern graphite condensers incorporate advanced design elements such as optimized flow paths, enhanced surface area for heat exchange, and careful consideration of pressure drop characteristics. These features combine to deliver exceptional performance in demanding operational environments where traditional metal condensers might fail or deteriorate rapidly.