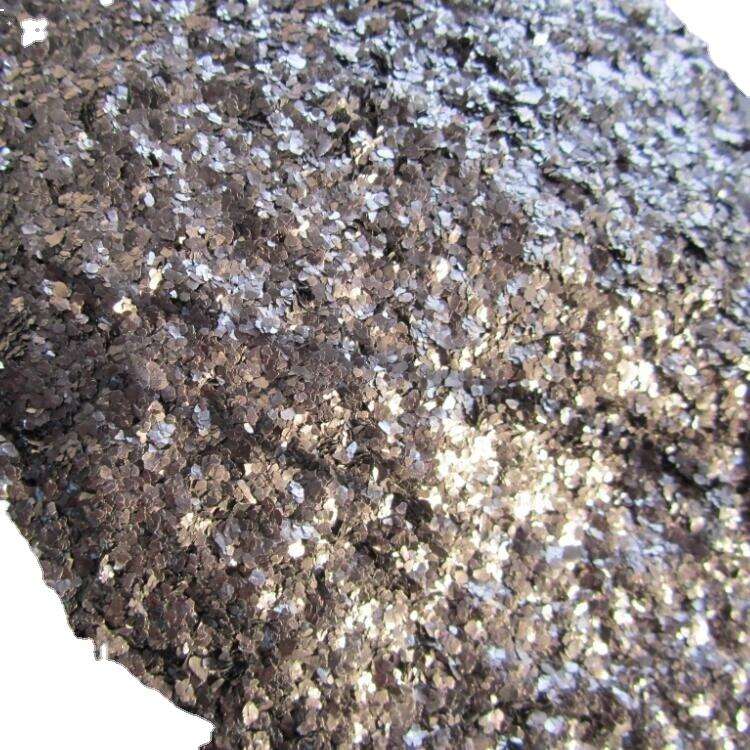

conductive graphite powder

Conductive graphite powder represents a versatile and highly efficient material that combines exceptional electrical conductivity with thermal stability. This specialized form of carbon consists of finely ground particles that maintain graphite's characteristic layered structure while offering enhanced conductivity properties. The powder's unique composition enables it to conduct electricity effectively while remaining chemically inert, making it ideal for various industrial applications. Its particle size typically ranges from submicron to several microns, allowing for optimal performance in different use cases. The powder's primary functions include serving as a conductive additive in batteries, providing electromagnetic interference (EMI) shielding, and acting as a crucial component in various electrical applications. In manufacturing processes, conductive graphite powder demonstrates remarkable stability at high temperatures and maintains its conductivity across a wide range of environmental conditions. Its ability to form uniform dispersions in various matrices makes it particularly valuable in creating conductive coatings, composites, and electrodes. The material's natural lubricating properties, combined with its conductivity, make it an excellent choice for applications requiring both electrical conductivity and reduced friction.