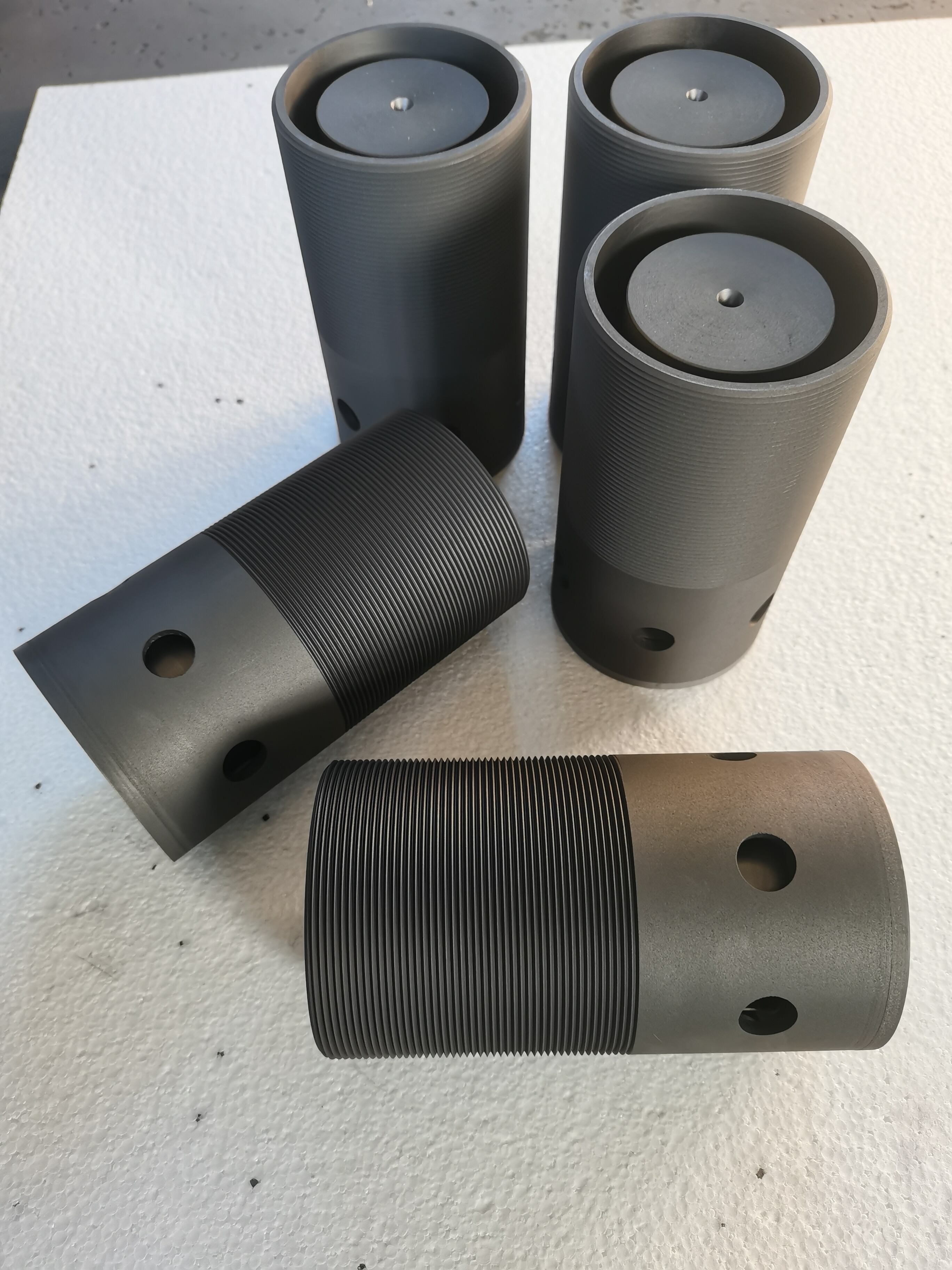

graphite molds for metal

Graphite molds for metal casting represent a crucial advancement in metallurgical processes, offering superior performance in high-temperature applications. These specialized molds are engineered from high-quality graphite materials, designed to withstand extreme temperatures while maintaining dimensional stability. The inherent properties of graphite, including excellent thermal conductivity and low thermal expansion, make these molds ideal for precise metal casting operations. They excel in applications requiring intricate details and complex geometries, particularly in precious metal casting, automotive parts manufacturing, and industrial component production. The molds feature carefully designed gating systems that ensure optimal metal flow and reduced turbulence during the casting process. Their non-wetting characteristics prevent metal adhesion, facilitating easy release of finished parts and extending mold life. Advanced manufacturing techniques allow for precise machining of these molds, ensuring accuracy in final product dimensions. The thermal shock resistance of graphite enables rapid heating and cooling cycles, significantly improving production efficiency. These molds are particularly valuable in continuous casting operations where consistent quality and dimensional accuracy are paramount.