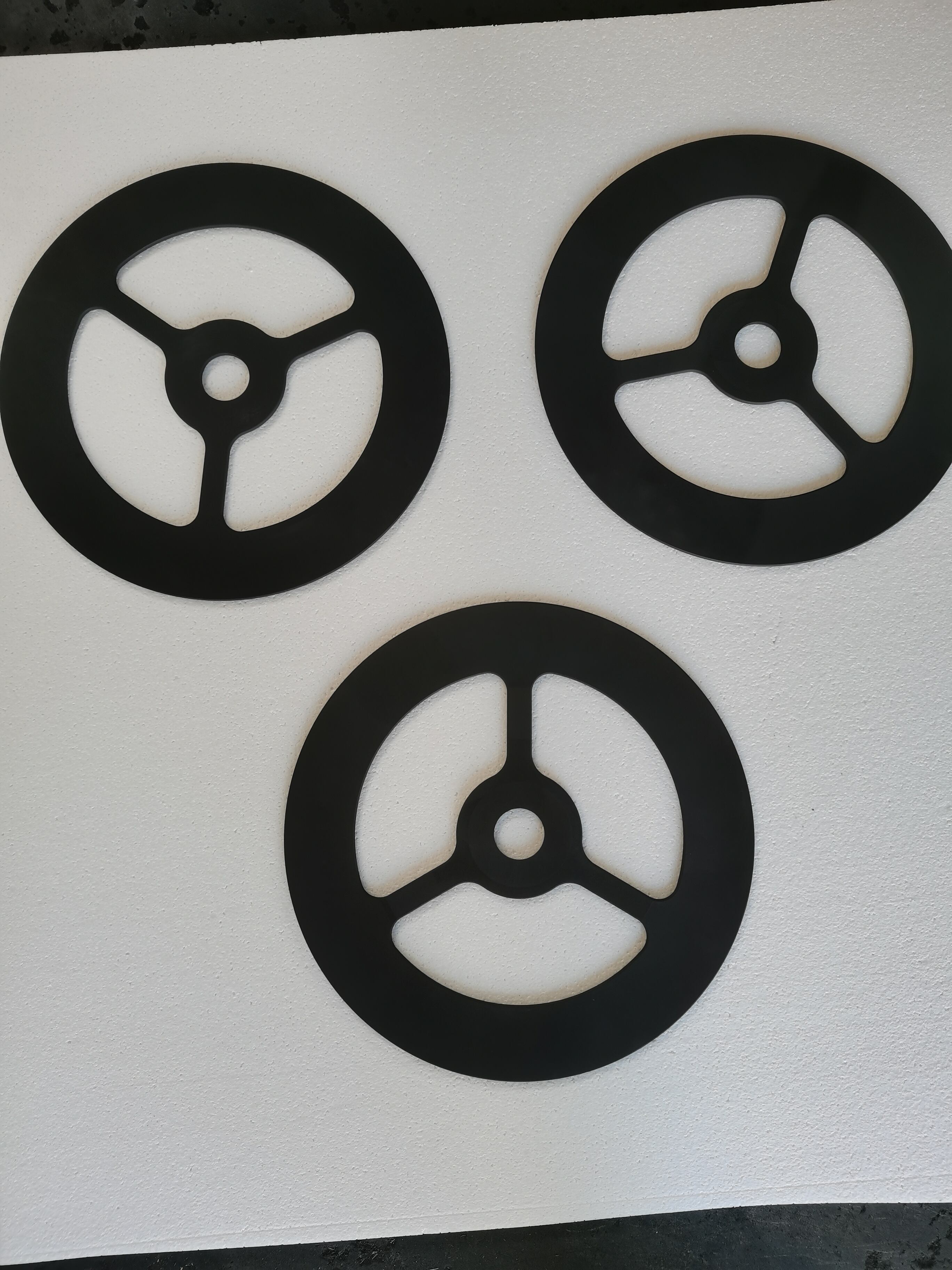

graphite crucibles

Graphite crucibles are essential industrial vessels designed for high-temperature metallurgical processes, featuring exceptional thermal conductivity and chemical resistance. These specialized containers are manufactured from high-purity graphite, making them ideal for melting and holding various metals, alloys, and other materials at extreme temperatures. The crucibles feature a dense microstructure that ensures superior thermal shock resistance and prevents metal penetration, while their high carbon content provides excellent thermal stability up to 3000°C. They are particularly valued in precious metal casting, semiconductor production, and laboratory applications where precise temperature control and material purity are paramount. The crucibles' unique composition allows for rapid heating and cooling cycles while maintaining structural integrity, reducing production time and energy consumption. Advanced manufacturing techniques ensure uniform wall thickness and controlled porosity, resulting in extended service life and consistent performance. These vessels are available in various sizes and shapes to accommodate different industrial needs, from small-scale laboratory work to large industrial operations, making them versatile tools in metallurgical processes.